Dealing with a faulty flexible wire in your car can be frustrating. Whether it’s a broken wire in your door, a frayed wire under the hood, or a damaged wire in your dashboard, this guide will equip you with the knowledge to diagnose and repair these common car electrical issues. Knowing how to fix a flexible wire for your car can save you time and money. Let’s dive in!

If you’re looking for help with your car speakers, check out this guide on how to fix car speaker.

Identifying the Problem: Where’s the Break?

Before you can fix a flexible wire, you need to pinpoint the exact location of the damage. This often involves a bit of detective work. Start by visually inspecting the wire. Look for obvious signs of damage like fraying, cuts, burns, or corrosion. If the damage isn’t visible, you might need to use a multimeter to test for continuity. This involves checking for a complete electrical path along the wire.

Damaged Flexible Wire in a Car Door

Damaged Flexible Wire in a Car Door

Gathering Your Tools and Materials

Having the right tools makes any repair job easier. For fixing a flexible wire, you’ll need some basic tools like wire strippers, electrical tape, heat shrink tubing (recommended), a soldering iron (for more permanent fixes), and of course, replacement wire of the same gauge as the damaged one. Don’t forget a multimeter for testing!

Repairing the Broken Wire: Step-by-Step Guide

- Disconnect the battery: Safety first! Always disconnect the car battery’s negative terminal before working on any electrical components.

- Access the damaged wire: This might involve removing panels, trim, or other components to get to the wire. Be careful not to damage anything else in the process.

- Prepare the wire: Strip a small section of insulation from both ends of the damaged wire, exposing the copper strands. Do the same for the replacement wire.

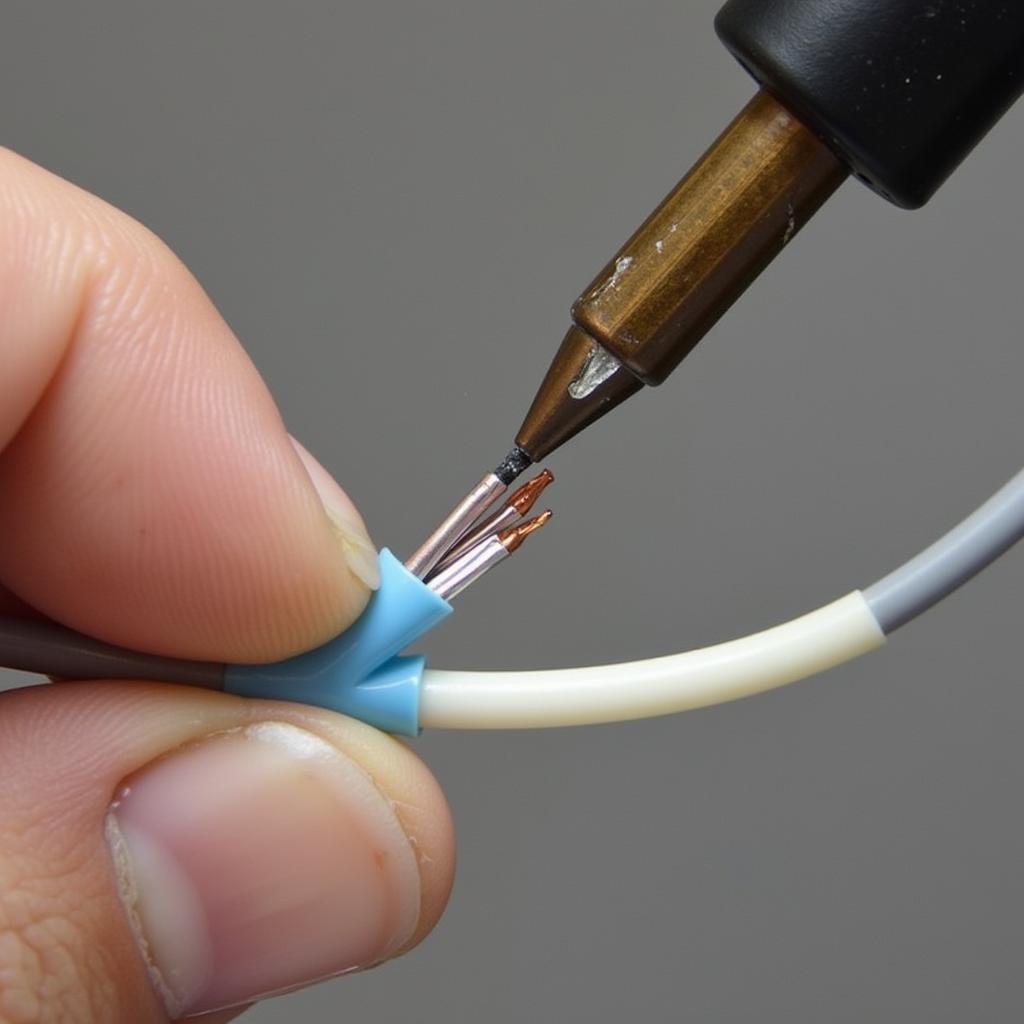

- Soldering (Recommended): For a strong and reliable connection, solder the replacement wire to the existing wire. Use heat shrink tubing to cover the soldered connection and protect it from the elements.

- Alternative to Soldering (Twist and Tape): If you don’t have a soldering iron, you can tightly twist the wires together and then securely wrap the connection with high-quality electrical tape. This method is less reliable than soldering, especially in areas exposed to moisture or vibration.

- Testing the repair: Reconnect the battery and test the component that was affected by the broken wire. Make sure everything is working correctly.

- Reassembly: Put everything back together in the reverse order of disassembly.

Soldering a Flexible Wire Repair in a Car

Soldering a Flexible Wire Repair in a Car

Need to find a cost-effective solution for fixing your car’s windows? Check out these cheapest places to fix car windows.

Preventing Future Wire Damage

Prevention is always better than cure! Regularly inspect your car’s wiring for signs of wear and tear. Secure any loose wires with zip ties or clips to prevent them from rubbing against sharp edges or getting pinched. Applying dielectric grease to connectors can help prevent corrosion.

When to Seek Professional Help

While many flexible wire repairs can be handled by DIY enthusiasts, some situations require professional assistance. If you’re dealing with complex wiring systems, multiple damaged wires, or if you’re simply uncomfortable working with electrical components, it’s best to take your car to a qualified mechanic.

“A common mistake people make is using the wrong gauge wire for the repair,” says John Smith, a veteran automotive electrician with over 20 years of experience. “Using a wire that’s too thin can lead to overheating and even fire hazards.” He also emphasizes the importance of properly insulating the repaired connection to prevent corrosion and short circuits. “A little extra care can save you a lot of trouble down the road.”

Conclusion

Knowing how to fix a flexible wire for your car is a valuable skill for any car owner. By following the steps outlined in this guide, you can tackle many common wire repair jobs yourself. Remember to prioritize safety and don’t hesitate to seek professional help when needed. For further assistance or inquiries, connect with AutoTipPro at +1 (641) 206-8880 or visit our office at 500 N St Mary’s St, San Antonio, TX 78205, United States.

Completed Flexible Wire Repair in a Car

Completed Flexible Wire Repair in a Car

FAQ

- What gauge wire should I use for car repairs? Match the gauge of the replacement wire to the existing wire. Using a different gauge can cause electrical problems.

- Can I use regular tape instead of electrical tape? No, regular tape is not designed for electrical applications and can create a fire hazard.

- What is heat shrink tubing? Heat shrink tubing is a type of tubing that shrinks when heated, providing a tight and insulating seal around wire connections.

- How do I test a wire for continuity? Use a multimeter set to the continuity setting. Touch one probe to each end of the wire. A beep indicates continuity.

- What should I do if I can’t find the break in the wire? If you can’t locate the break visually or with a multimeter, it may be necessary to consult a professional mechanic.

- Is it safe to repair car wiring myself? If you’re comfortable working with electrical components and follow safety precautions, you can repair many simple wiring issues yourself. However, complex repairs are best left to professionals.

- What are some signs of a faulty wire? Signs include flickering lights, malfunctioning electrical components, blown fuses, or a burning smell.

Leave a Reply