Crankshafts On A Car Math Problem Using Vectors can be a complex topic, but understanding the basics of vector calculations and their application to crankshaft analysis can greatly assist automotive professionals in diagnosing and addressing engine issues. This article will break down the complexities of this topic, providing valuable insights into how vector math is used to analyze crankshaft operation.

Understanding Crankshaft Motion with Vectors

Crankshaft motion is inherently rotational, converting the reciprocating motion of the pistons into rotational power. Analyzing this motion requires a way to represent both magnitude and direction, which is where vectors come in. Vectors are mathematical tools used to represent physical quantities that have both magnitude and direction. In the context of a crankshaft, vectors can describe the position, velocity, and acceleration of each crankpin.

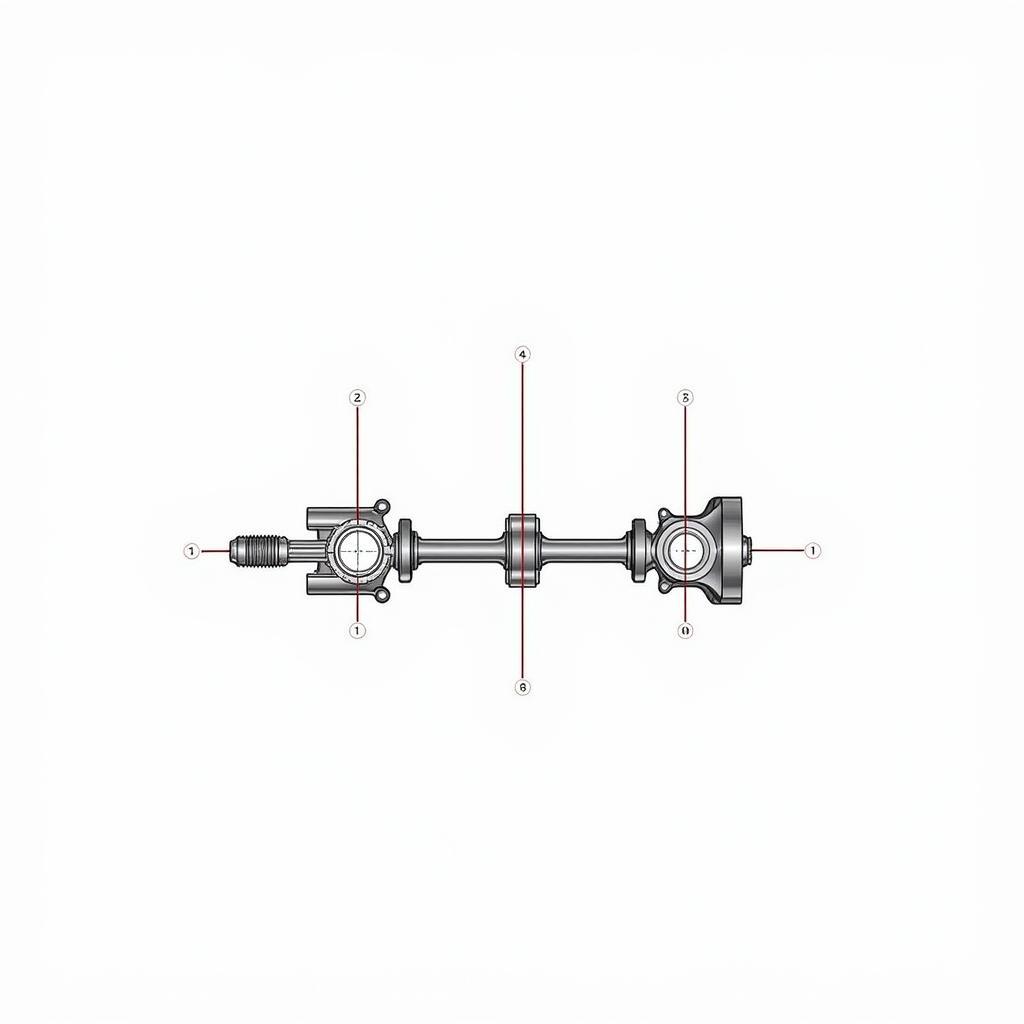

Crankshaft Vector Diagram

Crankshaft Vector Diagram

Imagine the crankshaft rotating. Each crankpin traces a circular path. We can represent the position of a crankpin at any given moment by a vector pointing from the center of the crankshaft to the crankpin. The length of the vector represents the radius of the crank circle (the crank throw), and the angle of the vector represents the crankshaft’s rotational angle.

Calculating Crankshaft Forces using Vectors

Analyzing crankshaft forces is crucial for understanding engine balance and potential stress points. These forces, arising from combustion pressure and inertia, act on the crankpins and can be represented as vectors.

By using vector addition, we can determine the net force acting on the crankshaft at any given point. This information is critical for designing robust crankshafts that can withstand these forces without failure. For example, understanding the vector sum of forces allows engineers to minimize vibrations and ensure smooth engine operation.

Applying Vector Math to Crankshaft Balancing

Crankshaft balancing is essential for minimizing engine vibrations and ensuring longevity. Imbalance can lead to excessive wear and tear on engine components. Vector math plays a key role in determining the magnitude and location of counterweights needed to balance the crankshaft.

The inertial forces generated by the rotating crankshaft and reciprocating components can be represented as rotating vectors. By carefully analyzing these vectors, engineers can determine the optimal size and placement of counterweights to effectively cancel out these forces, resulting in a smoothly balanced engine.

Analyzing Crankshaft Dynamics with Vector Calculus

More advanced applications of vector math, such as vector calculus, can be used to analyze the dynamics of the crankshaft. This includes calculating the velocity and acceleration of the crankpins, which are crucial for understanding engine performance and predicting potential issues.

“Understanding the vector nature of crankshaft motion allows us to precisely model and analyze complex engine dynamics, leading to optimized engine designs and improved performance.” – Dr. Emily Carter, Mechanical Engineering Professor specializing in Automotive Dynamics

Using Vectors for Crankshaft Design and Optimization

Crankshaft design and optimization heavily rely on vector calculations. By modeling the crankshaft and its forces using vectors, engineers can simulate different scenarios and optimize the design for strength, durability, and performance. This can lead to lighter, stronger crankshafts that improve engine efficiency and reduce emissions.

“The application of vector analysis in crankshaft design has revolutionized the automotive industry, allowing us to build more efficient and powerful engines.” – Mr. David Miller, Senior Automotive Engineer specializing in Powertrain Development

Conclusion

Crankshafts on a car math problem using vectors are an integral part of understanding engine operation. Utilizing vector principles, we can analyze forces, motion, and balance, ultimately leading to improved engine design, performance, and longevity. If you need further assistance or have questions about automotive issues, don’t hesitate to reach out to the experts at AutoTipPro.

Contact us at +1 (641) 206-8880 or visit our office at 500 N St Mary’s St, San Antonio, TX 78205, United States.

Leave a Reply