Friction is the enemy of speed in a mousetrap car. Understanding problems related to friction in a mousetrap car is key to maximizing its performance. This article will delve into common friction-related issues, exploring solutions and providing practical advice to help you get your mousetrap car running smoothly and efficiently.

Identifying Friction Points in Your Mousetrap Car

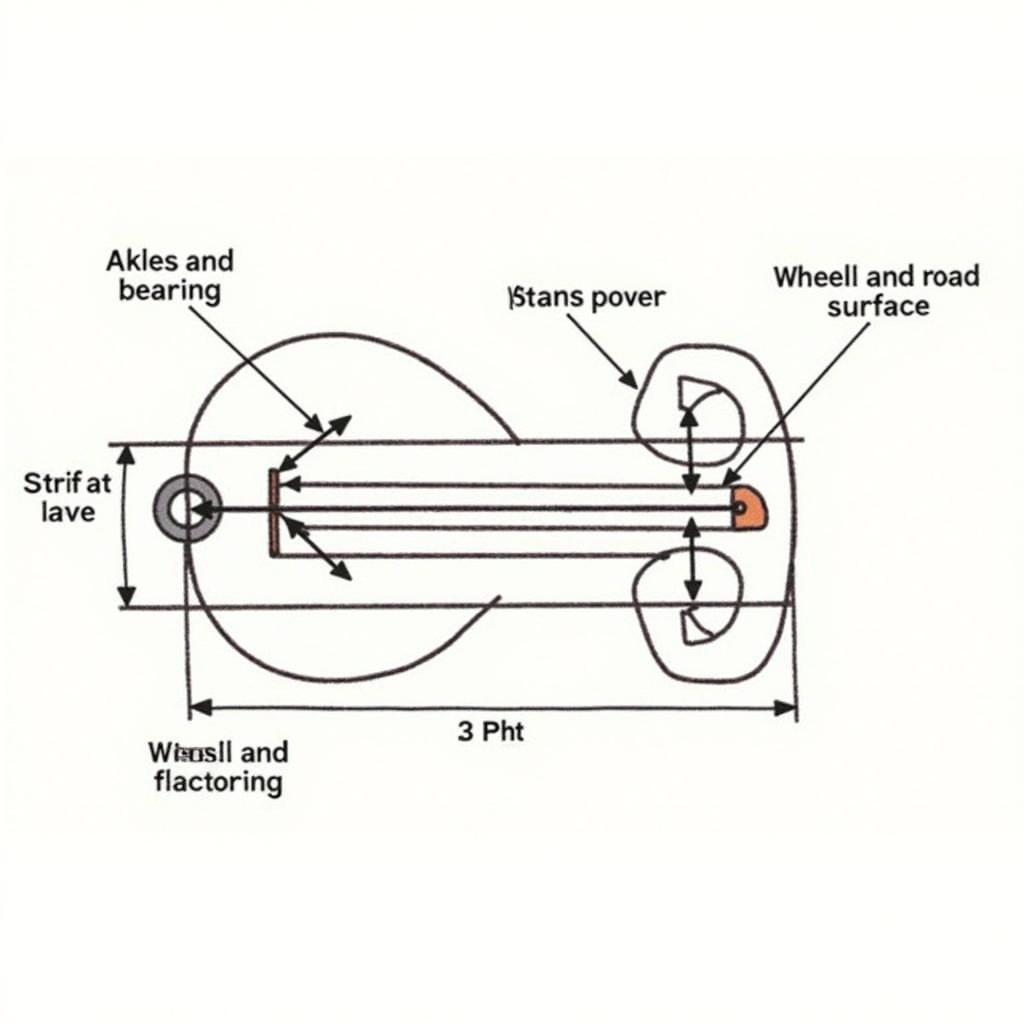

Friction is a force that opposes motion, and in a mousetrap car, it can significantly slow things down. Pinpointing the areas where friction is a major factor is the first step towards reducing its impact. Several common friction points exist in most mousetrap car designs. These include the axles and bearings, where the axle rotates within the chassis; the wheels and the surface they roll on; and the string and lever arm interface, where the string winds around the axle. Identifying these areas is crucial for effective troubleshooting.

Identifying Friction Points in Mousetrap Cars

Identifying Friction Points in Mousetrap Cars

One effective method to identify friction points is the “spin test”. Wind the string tightly and then release the lever arm. Observe how long the wheels spin freely. A car with minimal friction should spin for an extended period. If the wheels stop quickly, you know friction is at play.

Axle Friction: A Common Culprit

Axle friction is a significant source of energy loss in mousetrap cars. This friction occurs where the axle rotates within the chassis. Minimizing this friction is crucial for optimizing performance. Using smooth, polished axles is essential, as rough surfaces create more friction.

Wheel-to-Surface Friction: The Importance of the Right Tires

The interaction between the wheels and the surface they travel on also creates friction. The type of wheels and the surface material can drastically impact performance. Smooth surfaces generally offer less resistance than rough ones. Choosing the right tires is crucial. For example, hard wheels perform well on smooth surfaces, while softer, more grippy tires are better for rougher terrain.

Reducing Friction for Maximum Performance

Once you’ve identified the primary friction points, you can implement strategies to reduce their impact. A few simple modifications can drastically improve your mousetrap car’s performance.

Lubrication: A Simple Solution with Big Impact

Lubrication is a highly effective way to reduce friction between moving parts. Applying a small amount of lubricant to the axles and bearings can significantly improve the car’s efficiency. Be careful not to over-lubricate, as this can attract dust and debris, negating the positive effects. Dry lubricants like graphite powder or Teflon spray are excellent options.

Bearing Selection: Choosing the Right Bearings for Your Car

Using high-quality bearings is another important step in minimizing friction. Ball bearings or even simple straw bearings can drastically reduce the friction compared to just having the axle rub against the chassis. Properly sized and aligned bearings are crucial for optimal performance.

Optimizing the String and Lever Arm: Ensuring a Smooth Transfer of Energy

The string and lever arm are critical components for transferring energy from the mousetrap to the axle. Ensure the string winds smoothly around the axle without slipping or binding. Using a thin, strong, and flexible string is essential. A well-designed lever arm can also optimize the transfer of energy and minimize friction.

“Proper lubrication is the cheapest and easiest way to improve the performance of your mousetrap car,” says Dr. Emily Carter, a mechanical engineer specializing in tribology. “A small amount of a suitable lubricant can significantly reduce friction and boost efficiency.”

“Selecting the right bearings is like choosing the right shoes for a marathon runner,” adds John Smith, a veteran mousetrap car builder and competition judge. “The right bearings can make all the difference in minimizing friction and maximizing speed.”

“Don’t underestimate the importance of a smooth string and a well-designed lever arm,” advises Sarah Johnson, a physics teacher and mousetrap car enthusiast. “These components are crucial for efficiently transferring energy from the mousetrap to the wheels.”

Conclusion

Addressing problems related to friction in a mousetrap car is essential for maximizing its performance. By understanding the key friction points and implementing effective strategies to reduce friction, you can significantly improve your car’s speed and efficiency. Remember, minimizing friction is an ongoing process that requires careful observation, experimentation, and fine-tuning. For further assistance or personalized advice, contact AutoTipPro at +1 (641) 206-8880 or visit our office at 500 N St Mary’s St, San Antonio, TX 78205, United States.

FAQ

-

What is the most common cause of friction in a mousetrap car? Axle friction is often the biggest culprit.

-

What type of lubricant is best for a mousetrap car? Dry lubricants like graphite powder or Teflon spray are recommended.

-

How can I reduce wheel-to-surface friction? Use smooth wheels on smooth surfaces and consider softer tires for rougher terrain.

-

What’s the benefit of using bearings in a mousetrap car? Bearings drastically reduce friction compared to axles rubbing directly against the chassis.

-

How can I tell if my mousetrap car has excessive friction? Perform the “spin test” – a car with minimal friction should spin for a long time after releasing the lever arm.

-

What’s the best string material for a mousetrap car? A thin, strong, and flexible string is ideal.

-

How can I improve the efficiency of my lever arm? Ensure the string winds smoothly and consider using a pulley system.

Leave a Reply