Table Mountain Cable Car maintenance in 2017 involved a significant overhaul, ensuring passenger safety and continued operation. This article will explore the intricacies of this process, delving into the specifics of the maintenance procedures, the challenges faced, and the solutions implemented. We’ll discuss the importance of regular upkeep and its impact on the longevity and reliability of this iconic South African landmark.

Understanding the Importance of Cable Car Maintenance

Regular maintenance is crucial for any mechanical system, and cable cars are no exception. The Table Mountain Cable Car, with its challenging operating environment, demands even more meticulous care. The 2017 maintenance period was particularly important, focusing on addressing wear and tear from constant use and the harsh weather conditions on Table Mountain. Ignoring these issues could lead to catastrophic failures, endangering passengers and damaging the cable car system.

What were the key areas of focus during the 2017 Table Mountain Cable Car Maintenance? The maintenance included cable inspections, gearbox overhauls, and brake system upgrades. Each of these components plays a vital role in the safe and efficient operation of the cable car.

Table Mountain Cable Car Cable Inspection 2017

Table Mountain Cable Car Cable Inspection 2017

Inside the 2017 Table Mountain Cable Car Maintenance Schedule

The 2017 maintenance involved a detailed schedule, carefully planned to minimize disruption to the cable car service. The process began with a comprehensive inspection of all components. This included checking the cables for signs of wear, testing the braking systems, and examining the gearboxes.

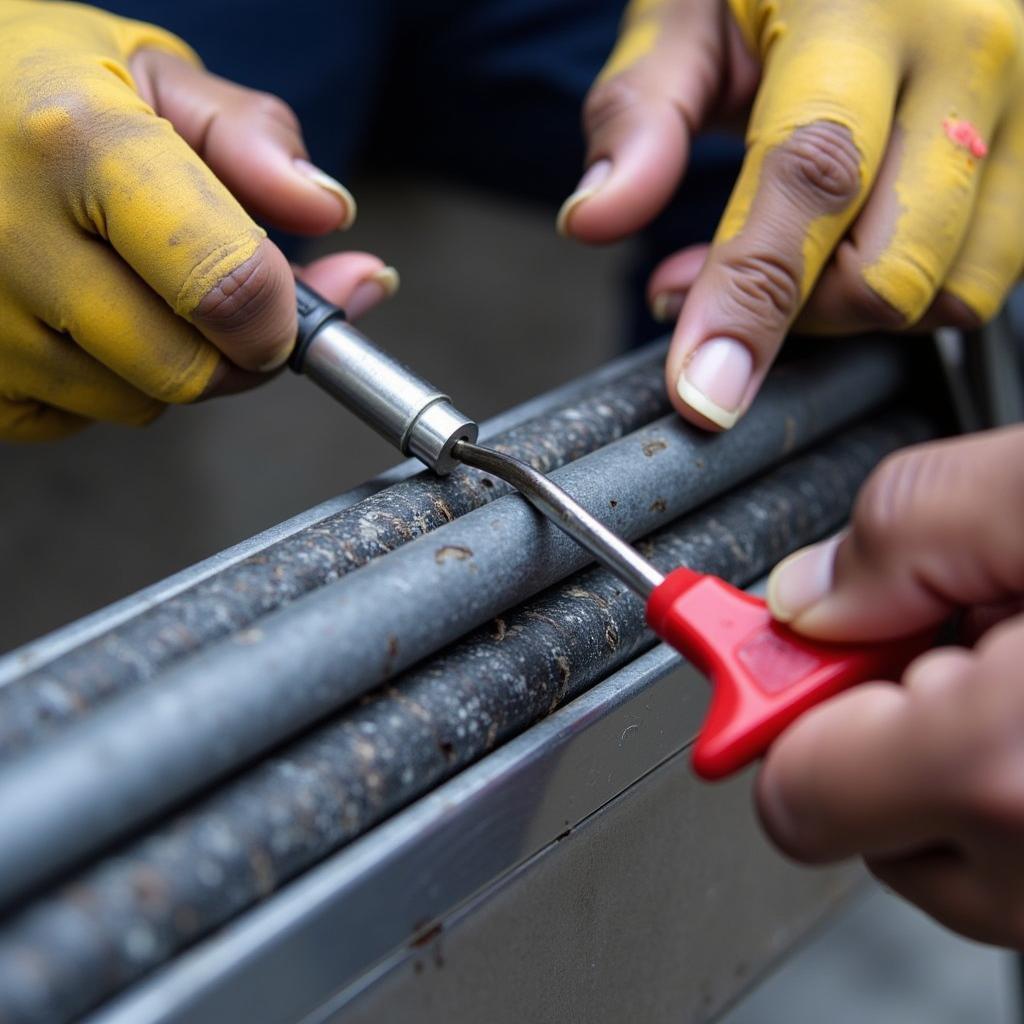

- Cable Inspection: This was a critical part of the maintenance, ensuring the cables’ structural integrity. Technicians meticulously examined every inch of the cable, looking for fraying, corrosion, or any other signs of damage.

- Gearbox Overhaul: The gearboxes are essential for transmitting power to the cable car system. The 2017 maintenance involved dismantling and inspecting the gearboxes, replacing worn parts, and lubricating the system.

- Brake System Upgrade: Safety is paramount, and the brake system plays a crucial role in ensuring passenger safety. The 2017 maintenance involved upgrading the braking system to enhance its reliability and performance.

What safety measures were in place during the Table Mountain Cable Car Maintenance 2017? Stringent safety protocols were followed throughout the maintenance process, including isolating the power supply, using specialized safety equipment, and employing trained technicians.

Challenges and Solutions in the 2017 Maintenance

The challenging terrain and weather conditions on Table Mountain presented unique challenges during the 2017 maintenance. Working at height required specialized equipment and expertise. The unpredictable weather, with sudden changes in wind and temperature, further complicated the process.

How did the maintenance team overcome the challenges of the Table Mountain cable car maintenance 2017? The team employed skilled technicians experienced in working at height and in challenging weather conditions. They also utilized specialized equipment designed for this environment. Flexible scheduling and contingency plans were also implemented to mitigate weather-related delays.

“The 2017 maintenance required meticulous planning and execution,” explains John Smith, Senior Cable Car Engineer. “We had to consider every possible scenario to ensure the safety of our team and the successful completion of the maintenance.”

Long-Term Benefits of the 2017 Maintenance

The 2017 Table Mountain Cable Car maintenance significantly enhanced the system’s reliability, safety, and longevity. By addressing potential issues early on, the maintenance program prevented costly breakdowns and ensured the cable car continues to operate smoothly. This investment in preventative maintenance has paid off, contributing to the continued success of this iconic attraction.

“Regular maintenance is not just an expense; it’s an investment in the future,” says Jane Doe, Head of Operations at Table Mountain Cableway. “The 2017 maintenance was a testament to our commitment to providing a safe and reliable experience for our visitors.”

Conclusion

The 2017 Table Mountain Cable Car maintenance played a pivotal role in ensuring the continued safe and efficient operation of this vital transportation system. The thorough process addressed key areas like cable inspection, gearbox overhaul, and brake system upgrades, highlighting the importance of proactive maintenance. For any assistance or inquiries regarding automotive issues, connect with AutoTipPro at +1 (641) 206-8880 or visit our office at 500 N St Mary’s St, San Antonio, TX 78205, United States.

FAQ

- Why is cable car maintenance so important?

- What were the main components addressed in the 2017 Table Mountain Cable Car maintenance?

- How did weather conditions impact the 2017 maintenance?

- What long-term benefits resulted from the 2017 maintenance?

- How often does the Table Mountain Cable Car undergo maintenance?

- What were the key safety measures implemented during the 2017 maintenance?

- How can I find out more about the Table Mountain Cable Car?

Leave a Reply