Car maintenance turn rotors is a crucial aspect of ensuring optimal braking performance and overall vehicle safety. Neglecting this essential task can lead to decreased braking efficiency, vibrations, and even premature brake failure. This comprehensive guide will provide you with everything you need to know about turning rotors, from understanding the process to executing it like a seasoned professional.

Why is Turning Rotors Important?

Over time, brake rotors can develop uneven wear patterns, grooves, or warping due to friction and heat generated during braking. This uneven surface can compromise the contact between the brake pads and rotors, resulting in reduced braking power and a variety of unpleasant symptoms. Turning rotors restores a smooth and even surface, ensuring optimal contact and maximizing braking efficiency. It’s a cost-effective solution that can extend the life of your rotors and prevent more expensive repairs down the line.

Signs Your Rotors Need Attention

How do you know if your rotors are due for a turning? Pay attention to these telltale signs:

- Vibration or pulsation in the brake pedal: This is often the most noticeable symptom of warped or uneven rotors.

- Squealing or grinding noises during braking: While this can also indicate worn brake pads, it can also be a sign of rotor issues.

- Reduced braking performance: If your car takes longer to stop than usual, it’s a serious safety concern and could indicate a need for rotor servicing.

- Visible grooves or scoring on the rotor surface: A visual inspection can often reveal significant wear and tear.

The Process of Turning Rotors

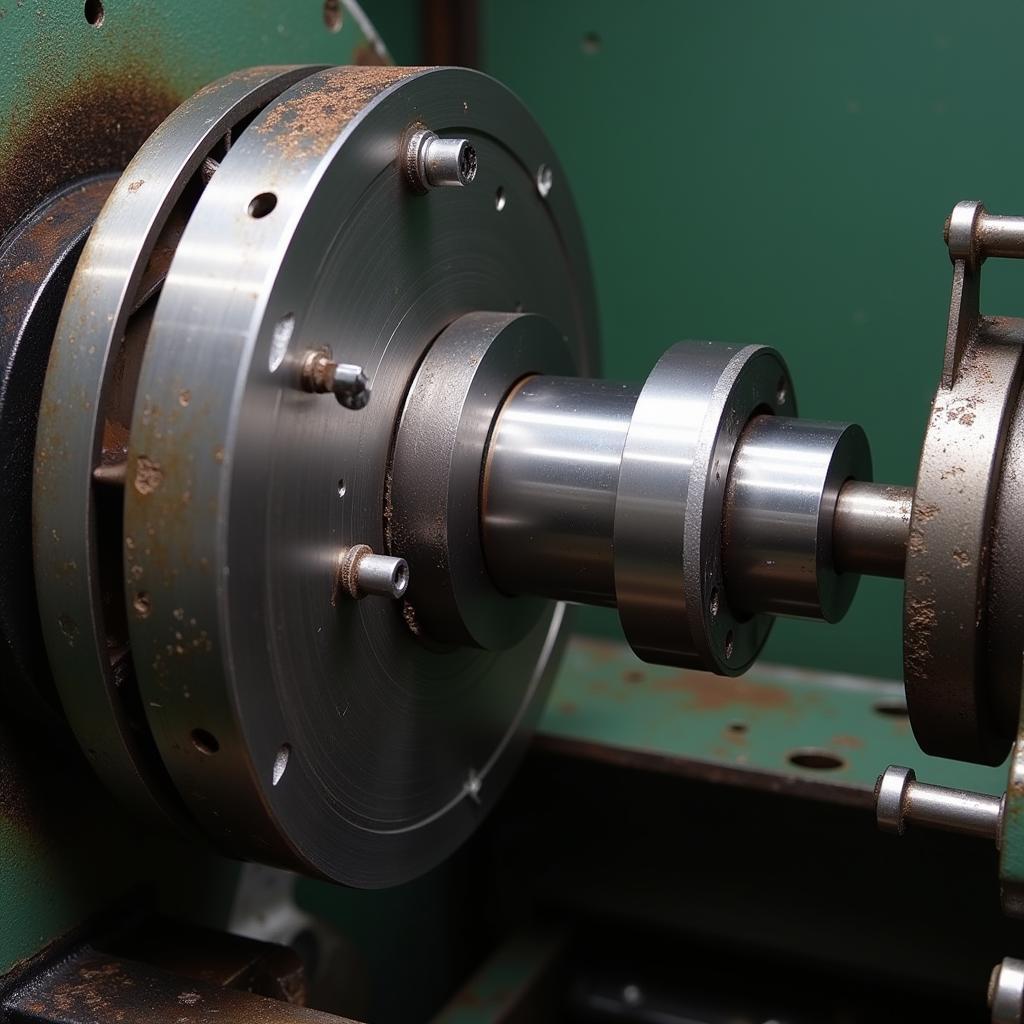

Turning rotors, also known as resurfacing or machining, involves removing a thin layer of metal from the rotor surface to create a smooth and even finish. This process is typically performed using a specialized lathe machine.

Steps Involved in Turning Rotors

- Remove the wheels and brake calipers: This provides access to the rotors.

- Mount the rotor on the lathe: The lathe secures the rotor and ensures precise machining.

- Turn the rotor: The lathe removes a small amount of metal from the rotor surface, eliminating imperfections.

- Measure rotor thickness: Ensure the rotor remains within the manufacturer’s minimum thickness specifications.

- Reinstall the rotors, calipers, and wheels: Properly torque all components to ensure safety.

Car Rotor Turning Process Using a Lathe Machine

Car Rotor Turning Process Using a Lathe Machine

DIY vs. Professional Rotor Turning

While some mechanically inclined individuals may choose to turn rotors themselves, it’s generally recommended to have this service performed by a qualified mechanic. They have the necessary expertise, tools, and experience to ensure the job is done correctly and safely.

“Proper rotor turning requires precision and specialized equipment,” says John Smith, ASE Certified Master Technician. “Attempting this without the right tools or knowledge can lead to further damage and compromise braking performance.”

When to Replace, Not Resurface

While turning rotors can be a cost-effective solution, there are times when replacement is necessary. If the rotors are severely worn, cracked, or below the minimum thickness specification, they must be replaced.

“Resurfacing rotors beyond their minimum thickness can significantly weaken them and increase the risk of failure,” advises Jane Doe, Automotive Engineer at Brake Systems Inc. “Safety should always be the top priority.”

Conclusion

Car maintenance turn rotors is a vital part of maintaining a safe and reliable vehicle. By understanding the signs of rotor problems and the importance of proper maintenance, you can ensure optimal braking performance and prevent costly repairs. Remember, regular brake inspections and timely servicing are key to keeping your car on the road and ensuring your safety. For any further assistance or inquiries, please don’t hesitate to contact AutoTipPro at +1 (641) 206-8880 or visit our office at 500 N St Mary’s St, San Antonio, TX 78205, United States.

FAQ

- How often should I have my rotors turned? It depends on driving habits and conditions, but it’s generally recommended to have them inspected during every brake service.

- Can I turn rotors myself? While possible, it’s generally recommended to have it done by a qualified mechanic.

- How much does it cost to turn rotors? The cost varies depending on location and service provider, but it’s typically less expensive than replacing rotors.

- What are the signs of warped rotors? Common signs include brake pedal pulsation, vibration, and reduced braking performance.

- How long do turned rotors last? This depends on driving habits and the quality of the resurfacing job.

- What is the minimum rotor thickness? Consult your vehicle’s owner’s manual for specific specifications.

- What happens if rotors are too thin? They can warp or crack, leading to brake failure.

Leave a Reply