The Car Sequencing Problem is a significant challenge in automotive manufacturing, impacting production efficiency and ultimately, your bottom line. This guide dives deep into the complexities of this issue, providing actionable solutions for car owners, repair shops, and automotive technicians alike. Let’s explore the intricacies of car sequencing and learn how to tackle it effectively.

car sequencing problem overview

Understanding the Car Sequencing Problem

The car sequencing problem arises from the need to optimize the order in which vehicles are assembled on a production line. Different car models require different options and features, and managing these variations efficiently is crucial. An improperly sequenced production line can lead to bottlenecks, delays, and increased costs. Imagine a scenario where several high-roof vans are scheduled consecutively, followed by a series of compact cars. This sequencing would require significant adjustments to the assembly line, causing delays and potentially halting production.

Why is Car Sequencing Important?

Effective car sequencing minimizes downtime and maximizes resource utilization. By strategically ordering vehicles based on their required options and features, manufacturers can streamline the production process, leading to improved efficiency and reduced costs. This optimized approach also ensures that the assembly line flows smoothly, minimizing the need for constant readjustments and preventing potential bottlenecks.

Common Causes of Car Sequencing Problems

Several factors can contribute to car sequencing challenges. These include:

- Variety of Car Models and Options: The increasing customization options available to customers lead to a wider range of vehicle configurations, making sequencing more complex.

- Supply Chain Disruptions: Delays in the delivery of parts or materials can disrupt the planned sequence and force manufacturers to reschedule production.

- Production Line Constraints: The physical limitations of the assembly line, such as the number of robots or the availability of specialized tools, can impact the sequencing process.

- Inadequate Planning and Scheduling: Poorly planned production schedules can exacerbate sequencing problems, leading to further delays and inefficiencies.

“In today’s automotive landscape, managing the complexity of car sequencing is crucial for staying competitive. A well-defined sequencing strategy can significantly impact a company’s profitability,” says John Miller, Senior Automotive Manufacturing Engineer.

Solutions for the Car Sequencing Problem

Several strategies can help mitigate car sequencing challenges. These include:

- Advanced Planning and Scheduling Software: Investing in sophisticated software can help manufacturers optimize their production schedules and anticipate potential sequencing issues.

- Lean Manufacturing Principles: Implementing lean principles can help streamline the production process, reducing waste and improving efficiency.

- Real-time Monitoring and Adjustments: Continuous monitoring of the production line allows for quick adjustments to the sequence if unexpected issues arise.

- Improved Communication and Collaboration: Effective communication between different departments, such as procurement, production, and logistics, is essential for efficient sequencing.

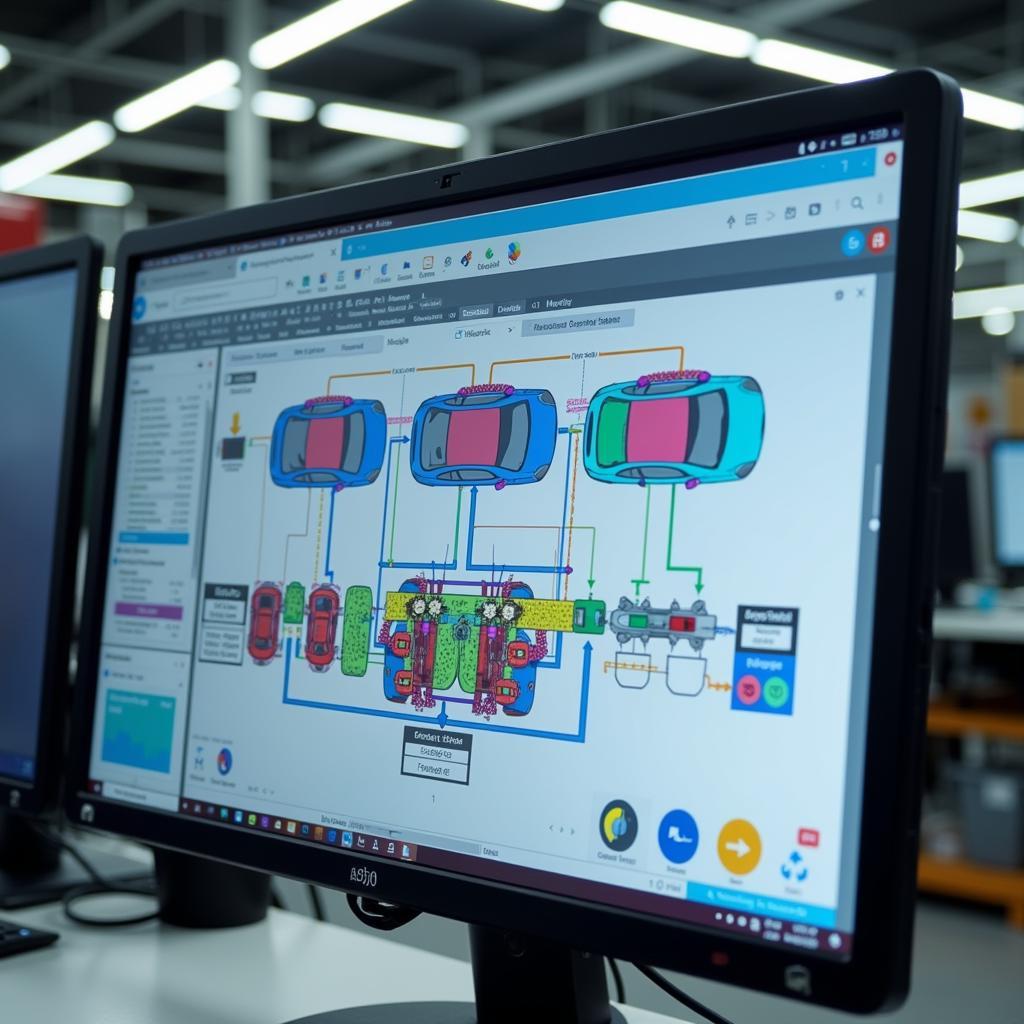

Car Sequencing Problem: Software Solution

Car Sequencing Problem: Software Solution

How Can Car Owners and Repair Shops Benefit from Understanding Car Sequencing?

While car sequencing is primarily a manufacturing concern, understanding its principles can also benefit car owners and repair shops. For instance, being aware of potential supply chain disruptions can help manage expectations regarding delivery times for new vehicles or replacement parts.

Conclusion: Optimizing Your Approach to the Car Sequencing Problem

The car sequencing problem is a complex challenge that requires a multifaceted approach. By implementing the strategies outlined in this guide, manufacturers, car owners, and repair shops can navigate these complexities effectively. Understanding the intricacies of car sequencing is critical for achieving optimal production efficiency and minimizing costs. For further assistance and personalized solutions, contact AutoTipPro at +1 (641) 206-8880 or visit our office at 500 N St Mary’s St, San Antonio, TX 78205, United States.

“Effective car sequencing isn’t just about optimizing production, it’s about delivering value to the customer,” says Sarah Johnson, Automotive Industry Consultant.

Leave a Reply