A failing idler pulley bearing can cause a range of issues, from annoying squealing noises to serious engine damage. This guide provides a comprehensive overview of the Car Idler Pulley Bearing Problem, covering symptoms, diagnosis, replacement, and prevention.

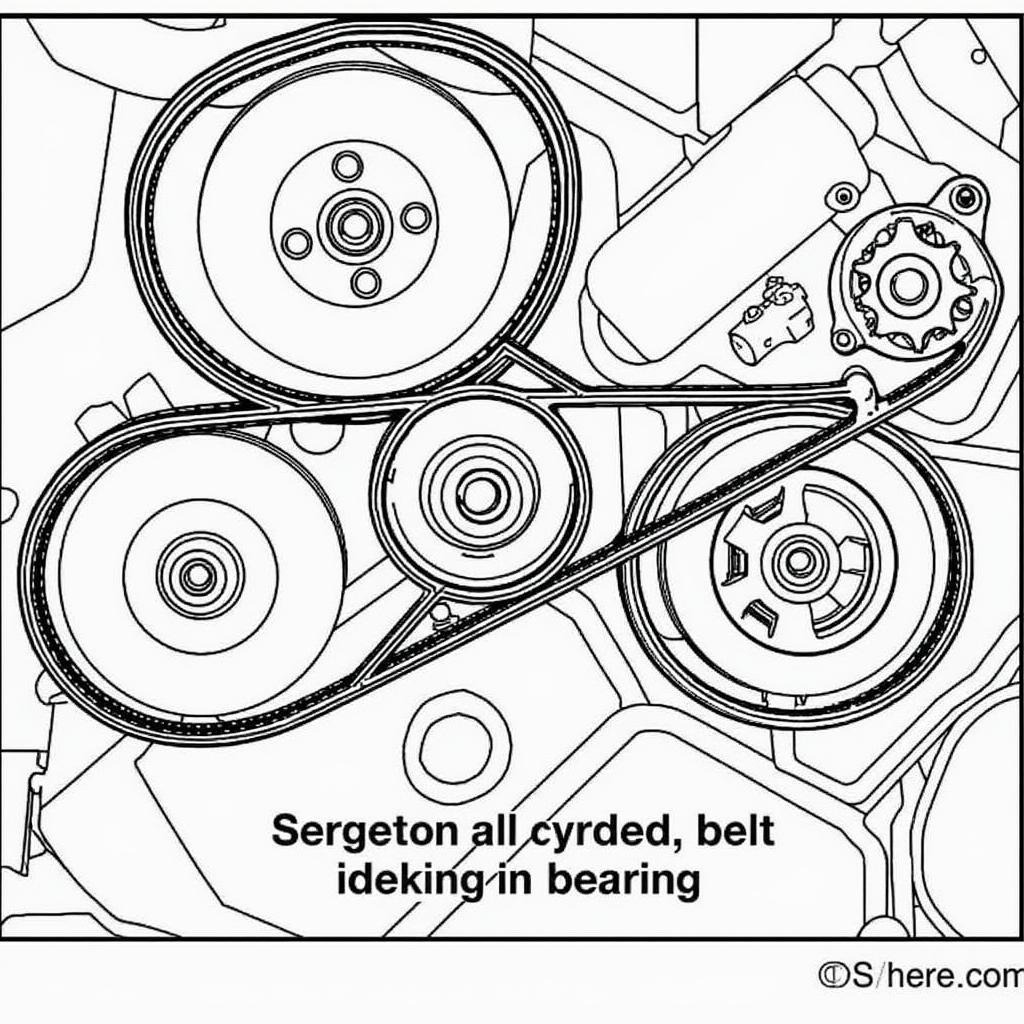

Car Idler Pulley Bearing Location

Car Idler Pulley Bearing Location

Understanding the Idler Pulley Bearing

The idler pulley bearing is a critical component of your car’s serpentine belt system. This system powers essential accessories like the alternator, power steering pump, and air conditioning compressor. The idler pulley, supported by its bearing, provides tension and proper routing for the serpentine belt. A malfunctioning bearing can disrupt this system, leading to performance issues and potential damage.

What causes a car idler pulley bearing problem? Several factors contribute to bearing failure. Exposure to extreme temperatures, contamination from dirt and debris, and general wear and tear are the most common culprits. Regular inspection and maintenance can help prevent premature failure.

Recognizing the Symptoms of a Bad Idler Pulley Bearing

How do you know if your idler pulley bearing is failing? Several tell-tale signs indicate a problem.

- Squealing or chirping noises: This is often the first and most noticeable symptom. The noise typically increases with engine speed and can be more prominent during cold starts.

- Visible wear or damage: Inspect the pulley for signs of wear, cracks, or wobble. A damaged pulley can indicate a failing bearing.

- Overheating or belt slippage: A seized bearing can cause the belt to slip, leading to overheating and potential damage to other components.

“A squeaking belt is often the first sign of a bad idler pulley bearing,” says John Miller, a seasoned automotive technician with over 20 years of experience. “Don’t ignore it, as it can lead to more expensive repairs down the line.”

Diagnosing the Problem

Diagnosing a car idler pulley bearing problem requires a systematic approach. Here’s how you can pinpoint the issue:

- Visual inspection: Carefully examine the pulley and belt for visible damage.

- Listen for unusual noises: Pay attention to any squealing or chirping sounds.

- Manual check: With the engine off, try to rotate the pulley by hand. A rough or gritty feeling indicates a bearing problem.

- Seek professional help: If you’re unsure, consult a qualified mechanic for a thorough diagnosis.

Replacing the Idler Pulley Bearing

Replacing the idler pulley bearing is a relatively straightforward procedure for those with some mechanical experience. However, if you’re not comfortable working on your car, it’s best to leave it to a professional.

Steps for Idler Pulley Bearing Replacement:

- Gather the necessary tools: You’ll need a serpentine belt tool, wrenches, and sockets.

- Relieve belt tension: Use the serpentine belt tool to release the tension on the belt.

- Remove the old pulley: Unbolt the idler pulley from its bracket.

- Install the new pulley: Bolt the new pulley in place and ensure it’s properly aligned.

- Reinstall the belt: Route the belt correctly and reapply tension.

- Test the system: Start the engine and check for proper operation.

“Replacing the idler pulley bearing is a preventative maintenance task that can save you headaches and money in the long run,” advises Sarah Chen, an automotive engineer.

Preventing Future Problems

Regular maintenance is crucial for preventing car idler pulley bearing problems. Here are some preventative measures:

- Regular inspections: Inspect the belt and pulley during routine maintenance.

- Belt replacement: Replace the serpentine belt at the recommended intervals.

- Address unusual noises promptly: Don’t ignore any squealing or chirping noises.

Conclusion

The car idler pulley bearing problem can be a nuisance, but with proper diagnosis and timely repair, it can be easily resolved. Regular maintenance is key to preventing future issues and ensuring the smooth operation of your vehicle. If you’re experiencing any issues with your idler pulley, don’t hesitate to connect with us at AutoTipPro for expert advice and assistance. Contact us at +1 (641) 206-8880 or visit our office at 500 N St Mary’s St, San Antonio, TX 78205, United States.

FAQ

- How much does it cost to replace an idler pulley bearing? The cost varies depending on the make and model of your car, but typically ranges from $50 to $200.

- Can I drive with a bad idler pulley bearing? It’s not recommended, as it can lead to further damage and potentially leave you stranded.

- How often should I replace the idler pulley bearing? While there’s no set interval, it’s a good idea to replace it along with the serpentine belt.

- What tools do I need to replace the idler pulley bearing? You’ll need a serpentine belt tool, wrenches, and sockets.

- What happens if the idler pulley bearing seizes? The belt can slip or break, causing various accessories to malfunction.

- Can a bad idler pulley bearing affect my engine? Yes, in severe cases, it can damage other components and potentially affect engine performance.

- How can I tell if my idler pulley bearing is going bad? Listen for squealing or chirping noises and inspect the pulley for visible wear.

Leave a Reply