Keeping your car wash conveyor system running smoothly is crucial for business. Car Wash Conveyor Maintenance not only minimizes downtime but also ensures customer satisfaction and protects your investment. This guide provides a deep dive into essential maintenance practices, troubleshooting tips, and best practices for maximizing the lifespan of your conveyor system.

Understanding the Importance of Car Wash Conveyor Maintenance

Regular car wash conveyor maintenance is the backbone of a successful car wash operation. Neglecting it can lead to costly repairs, unexpected downtime, and safety hazards. A well-maintained conveyor system contributes to a smoother, more efficient car wash process, leading to happier customers and a healthier bottom line. Think of it like regular oil changes for your car – a small investment upfront prevents major issues down the line. For those looking to enter the industry, understanding the different car wash and car maintenance types of industry is essential.

Key Components of a Car Wash Conveyor System

Understanding the core components of your conveyor system is the first step towards effective maintenance. These components typically include the chain, rollers, tracks, drive motor, and control system. Each part plays a vital role in the smooth operation of the conveyor.

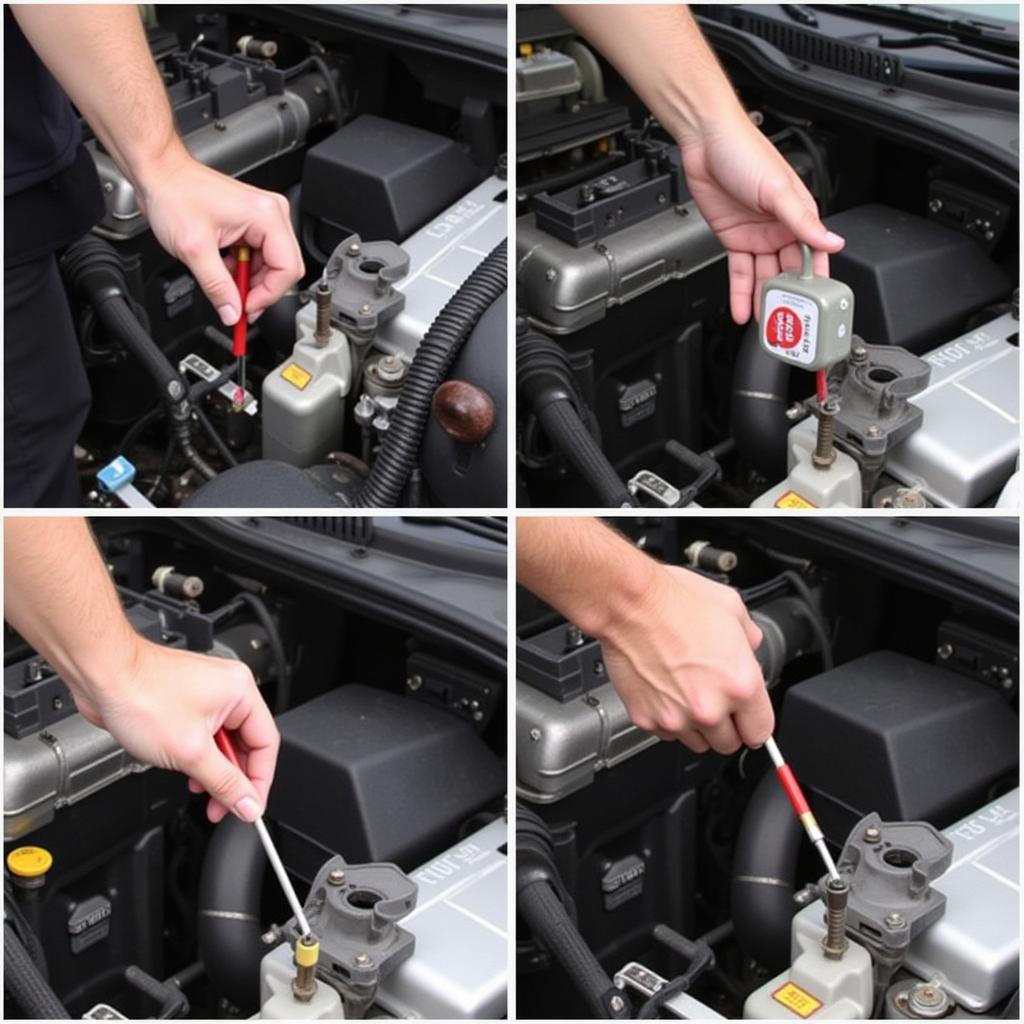

Inspecting the Chain of a Car Wash Conveyor

Inspecting the Chain of a Car Wash Conveyor

Preventive Maintenance: Your First Line of Defense

Preventive maintenance is about addressing potential problems before they become major headaches. This proactive approach not only saves you money but also ensures the safety of your staff and customers.

- Daily Inspections: Start each day by visually inspecting the conveyor system. Look for any signs of wear and tear, loose parts, or debris accumulation.

- Lubrication: Regularly lubricate the chain, rollers, and other moving parts according to the manufacturer’s recommendations. Proper lubrication reduces friction and extends the lifespan of these components.

- Chain Tension: Ensure the chain tension is within the specified range. A loose chain can cause slippage and damage, while an overly tight chain puts excessive strain on the motor and other parts.

- Cleaning: Regularly clean the tracks and remove any debris, such as dirt, leaves, or small stones. This prevents buildup and ensures smooth operation.

“Preventive maintenance is like brushing your teeth. It’s a small daily habit that prevents major problems down the road,” says John Davis, a seasoned car wash maintenance technician.

Creating a Maintenance Schedule

A well-defined maintenance schedule is essential for staying on top of your conveyor system’s needs. This schedule should outline daily, weekly, monthly, and annual maintenance tasks. Tailor the schedule to your specific car wash volume and usage.

Troubleshooting Common Conveyor Issues

Even with the best preventive maintenance, issues can still arise. Being able to quickly diagnose and address these problems is crucial for minimizing downtime.

- Conveyor Stops Unexpectedly: This could be caused by a tripped circuit breaker, a malfunctioning motor, or a jammed object in the track.

- Chain Slippage: Check the chain tension and ensure it’s within the specified range. If the chain is too loose, adjust it accordingly.

- Unusual Noises: Strange noises, such as grinding or squealing, can indicate a problem with the rollers, bearings, or chain.

Troubleshooting a Car Wash Conveyor Motor

Troubleshooting a Car Wash Conveyor Motor

“Knowing how to troubleshoot common conveyor problems empowers you to quickly fix minor issues and avoid costly downtime,” advises Sarah Miller, a Car Wash Tunnel Maintenance Manager. For those interested in this career path, explore the car wash tunnel maintenance manager job description.

Advanced Maintenance Techniques

For more complex maintenance tasks, consider consulting a qualified car wash maintenance technician. These technicians have the expertise and specialized tools to handle intricate repairs and replacements.

When to Call a Professional

While some maintenance tasks can be handled in-house, certain situations warrant the expertise of a professional. These include:

- Major component failures

- Complex electrical issues

- Extensive damage to the conveyor system

A detailed car wash maintenance job description provides further insight into the skills and responsibilities of these professionals.

Conclusion

Effective car wash conveyor maintenance is an ongoing process that requires diligence and attention to detail. By implementing a comprehensive maintenance program, you can minimize downtime, extend the life of your equipment, and ensure a smooth and efficient car wash operation. Remember, proactive maintenance is always better than reactive repairs. For expert advice and assistance with your car wash conveyor maintenance needs, connect with us at AutoTipPro. You can reach us at +1 (641) 206-8880 or visit our office at 500 N St Mary’s St, San Antonio, TX 78205, United States.

Leave a Reply