Hydraulic car lifts are essential tools in any auto repair shop, but like any complex piece of machinery, they can experience issues. This article dives deep into common Hydraulic Car Lift Problems and provides practical solutions for owners, mechanics, and technicians. Whether your lift is struggling to rise, leaking fluid, or making strange noises, we’ll help you troubleshoot and resolve the issue.

Understanding Common Hydraulic Car Lift Problems

Several problems can plague hydraulic car lifts, ranging from minor annoyances to major safety hazards. Recognizing the symptoms early can prevent costly repairs and downtime.

Low Hydraulic Fluid Levels

One of the most common hydraulic car lift problems is low hydraulic fluid. This can lead to slow lifting, jerky movements, or the inability to raise the lift to its full height. Regularly checking and topping off the fluid is crucial.

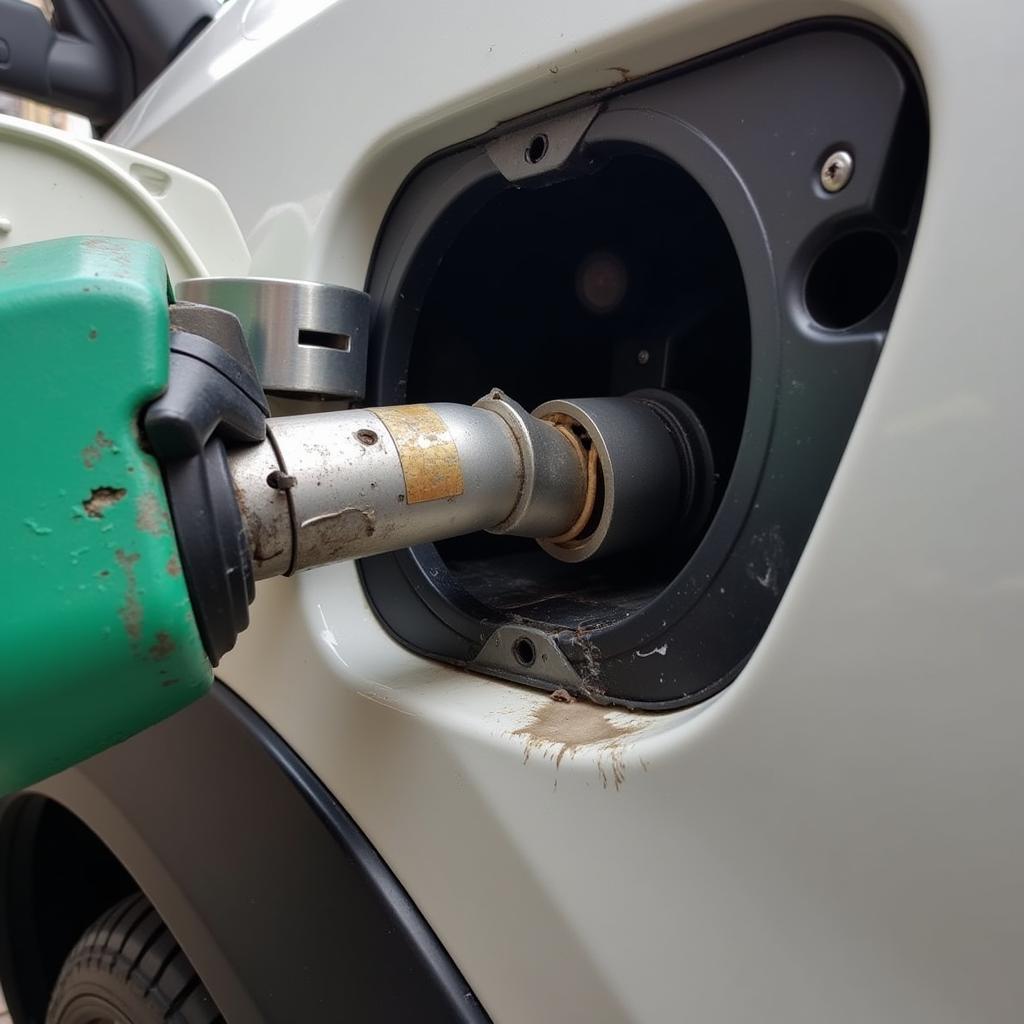

Hydraulic Fluid Leaks

Leaks in the hydraulic system can be a serious issue, leading to loss of pressure and potential lift failure. Leaks can occur in various locations, including hoses, cylinders, and fittings. Identifying and repairing leaks promptly is crucial for safety and efficiency.

Worn-Out Seals and O-Rings

Seals and O-rings are vital components in a hydraulic system, preventing fluid leakage. Over time, these components can wear out, crack, or become brittle, resulting in leaks and pressure loss.

Air in the Hydraulic System

Air trapped in the hydraulic system can cause the lift to operate erratically and reduce its lifting capacity. This can manifest as a spongy or jerky lifting action. Bleeding the system to remove air is a necessary maintenance procedure.

Electrical Issues

While primarily hydraulic, car lifts also rely on electrical components for operation. Problems with the motor, switches, or wiring can prevent the lift from working correctly. Troubleshooting electrical issues requires careful diagnosis and proper safety precautions.

Troubleshooting and Repairing Hydraulic Car Lift Problems

Diagnosing Hydraulic Car Lift Problems: A Step-by-Step Guide

- Inspect the hydraulic fluid level: Check the reservoir and top it off if necessary.

- Check for leaks: Inspect all hoses, cylinders, and fittings for signs of leakage.

- Listen for unusual noises: Strange noises can indicate problems with the pump, motor, or other components.

- Check the electrical system: Ensure the power supply is connected and test the motor, switches, and wiring.

Maintaining Your Hydraulic Car Lift

Regular maintenance is essential for preventing hydraulic car lift problems and ensuring its longevity. This includes:

- Regularly checking and topping off the hydraulic fluid.

- Inspecting hoses, cylinders, and fittings for leaks.

- Lubricating moving parts.

- Regularly bleeding the hydraulic system to remove air.

- Having a qualified technician inspect the lift annually.

“Regular maintenance is the key to preventing costly repairs and ensuring the safe operation of your hydraulic car lift,” advises John Miller, a seasoned automotive equipment technician with over 20 years of experience.

When to Call a Professional

While some minor hydraulic car lift problems can be addressed by knowledgeable owners or mechanics, more complex issues require the expertise of a qualified technician. If you’re unsure about the cause of the problem or lack the necessary tools and experience, it’s always best to seek professional assistance. “Don’t hesitate to call a professional if you encounter a problem you’re not comfortable addressing,” recommends Susan Davis, a certified automotive lift inspector.

Conclusion

Addressing hydraulic car lift problems promptly is crucial for safety and efficiency in any auto repair shop. By understanding the common issues, implementing preventative maintenance measures, and knowing when to call a professional, you can keep your lift operating smoothly for years to come. For expert assistance with your hydraulic car lift problems, contact AutoTipPro at +1 (641) 206-8880. Our office is located at 500 N St Mary’s St, San Antonio, TX 78205, United States.

FAQ

- How often should I check the hydraulic fluid level in my car lift? At least once a week.

- What type of hydraulic fluid should I use? Consult your lift’s owner’s manual for the recommended fluid type.

- How do I bleed the air from the hydraulic system? This procedure varies depending on the lift model. Refer to your owner’s manual for specific instructions.

- What are the signs of a worn-out hydraulic seal? Leaks, slow lifting, and jerky movements.

- Can I repair a hydraulic cylinder myself? It’s recommended to have a qualified technician perform cylinder repairs.

- How often should my car lift be professionally inspected? Annually.

- What should I do if my car lift suddenly stops working? Immediately lower the lift (if possible) and contact a qualified technician.

Leave a Reply