RC car screws can be a real pain, literally and figuratively. Whether you’re a seasoned racer or a weekend warrior, dealing with stripped, lost, or ill-fitting screws is an inevitable part of the RC car ownership experience. This guide will delve into the common Rc Car Screws Problem, offering solutions and preventative measures to keep your RC car running smoothly.

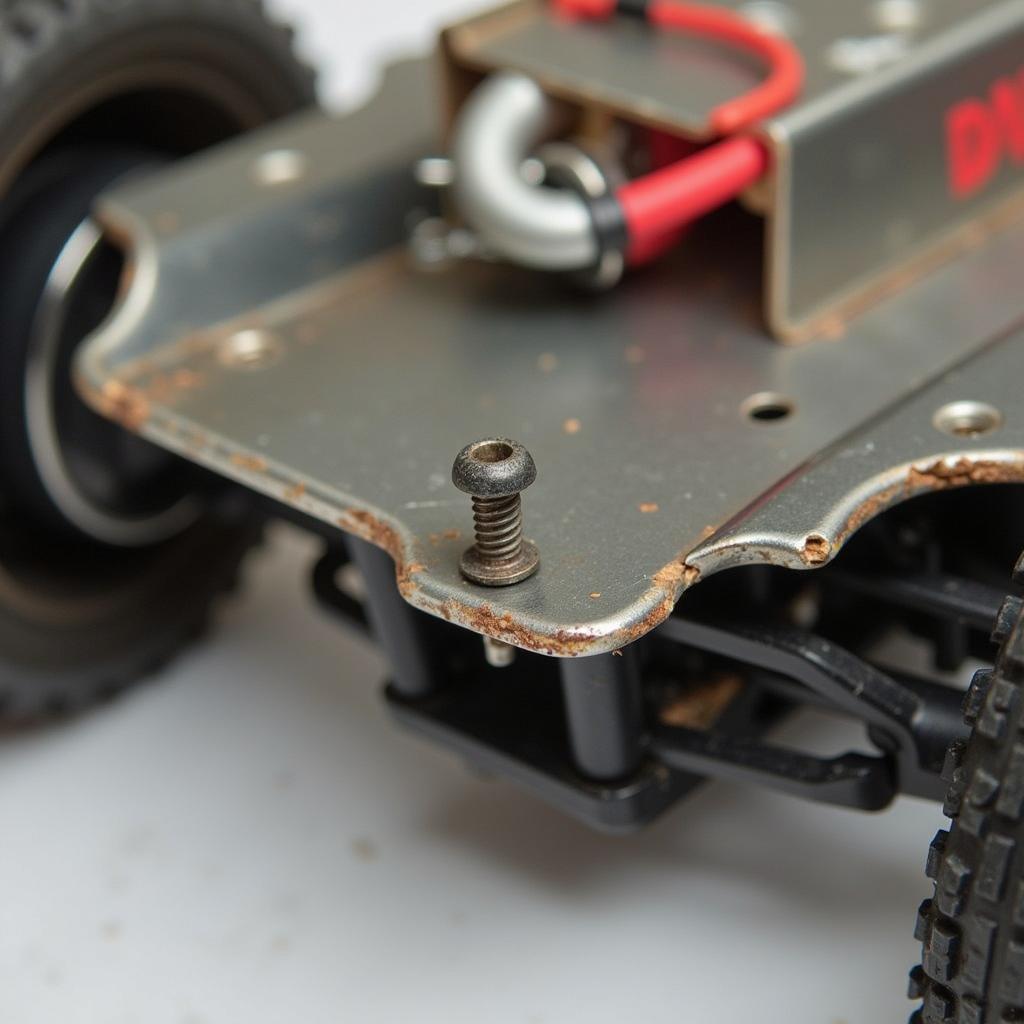

Stripped Screw on an RC Car Chassis

Stripped Screw on an RC Car Chassis

Identifying Common RC Car Screw Issues

Several issues can arise with rc car screws. Recognizing the specific problem is the first step towards finding the right solution.

- Stripped Screw Heads: This is perhaps the most common problem. Over-tightening, using the wrong size screwdriver, or simply wear and tear can lead to the screw head becoming rounded, making it impossible to remove with a standard screwdriver.

- Lost Screws: Small screws can easily become lost during maintenance or after a crash. This can be especially frustrating if the screw is crucial for holding a key component in place.

- Cross-threading: Forcing a screw into a hole that isn’t properly aligned can damage both the screw and the component it’s meant to secure.

- Incorrect Screw Length: Using a screw that is too long can damage internal components, while a screw that is too short won’t provide a secure hold.

- Corrosion: Exposure to moisture and dirt can lead to screws corroding, making them difficult to remove and potentially weakening the components they hold together.

Assorted RC Car Screws and Tools

Assorted RC Car Screws and Tools

Solving Your RC Car Screw Problems

Now that we’ve identified the common problems, let’s explore the solutions.

Dealing with Stripped Screws

For stripped screws, try these techniques:

- Use a rubber band: Place a small rubber band over the stripped screw head to provide extra grip for your screwdriver.

- Try a screw extractor: Screw extractors are specifically designed to remove stripped screws. They bite into the damaged head, allowing you to turn the screw out.

- Dremel a slot: Carefully use a Dremel tool to cut a slot in the stripped screw head, creating a new surface for a flathead screwdriver to grip.

If you experience problems with your car’s electrical system, which often involves screws, check out this helpful resource: car has electrical problems ecs.

Replacing Lost Screws

If you’ve lost a screw, don’t despair!

- Check your RC car manual: The manual often includes a parts list with screw sizes and specifications.

- Contact the manufacturer: They may be able to provide replacement screws or direct you to a retailer.

- Visit a hobby shop: Local hobby shops often carry a wide range of RC car parts, including screws.

Preventing Cross-threading

Preventing cross-threading is crucial for maintaining the integrity of your RC car:

- Start the screw by hand: Ensure the screw threads engage properly before using a tool.

- Use the correct size screwdriver: This will prevent slipping and reduce the risk of stripping the screw head.

- Apply even pressure: Don’t force the screw. If it feels tight, stop and check for alignment.

“Proper screw maintenance is essential for the longevity of your RC car,” advises Johnathan Davis, a leading RC car technician with 20 years of experience. “A little preventative care can save you a lot of headaches down the road.”

Addressing Corrosion

To combat corrosion:

- Use stainless steel screws: These are more resistant to rust.

- Apply threadlocker: This helps prevent screws from loosening and also seals out moisture.

- Clean your RC car regularly: Removing dirt and debris will help prevent corrosion.

Conclusion

Rc car screws problem, while common, are manageable. By understanding the common issues and implementing the solutions outlined in this guide, you can keep your RC car in top condition. Remember, preventative maintenance is key. Regularly checking and tightening screws, using the correct tools, and choosing high-quality screws will significantly reduce the likelihood of encountering these problems. If you need further assistance, feel free to contact us at AutoTipPro. Our team is here to help. You can reach us at +1 (641) 206-8880 or visit our office at 500 N St Mary’s St, San Antonio, TX 78205, United States.

“Taking the time to understand the basics of RC car maintenance, like dealing with screws properly, can significantly extend the life of your vehicle,” adds Maria Sanchez, a seasoned RC car racer and engineer. “It’s about understanding the mechanics and taking preventative measures.”

If your RC car exhibits electrical problems alongside screw issues, it’s worth investigating further. Sometimes, loose or corroded screws can contribute to electrical malfunctions. You might find these articles helpful: my car has electrical problem and how to tell if your car has electrical problems. For driving advice with electrical issues, consult can i drive car when the electrical problems. Another useful resource on diagnosing electrical problems is how to tell if a car has electrical problems.

FAQ

- What type of screws are typically used in RC cars? RC cars commonly use small machine screws, often with Phillips or hex heads.

- Where can I find replacement screws for my RC car? Check your manual, contact the manufacturer, or visit a local hobby shop.

- What is the best way to prevent stripped screws? Use the correct size screwdriver and avoid over-tightening.

- Can I use any type of threadlocker on my RC car screws? Choose a threadlocker specifically designed for metal-to-metal applications.

- How often should I check and tighten the screws on my RC car? It’s a good idea to check them after each run and tighten as needed.

- What should I do if a screw is stuck and won’t budge? Try using a penetrating oil or heat to loosen it before attempting to remove it.

- What is the best way to organize my RC car screws? Use a compartmentalized container or a magnetic parts tray.

Leave a Reply